Heritage Seeds have been harvesting from heathland and grassland communities since the mid-eighties, our first contract was an oil pipe-line crossing several SSSIs in Dorset. We started using vacuum machines but quickly adapted and now use low impact brush harvesters.

The Process

The Donor Site

A site free from noxious weeds and improvement by overseeding. The most valuable communities are normally steeply sloping or have poor access.

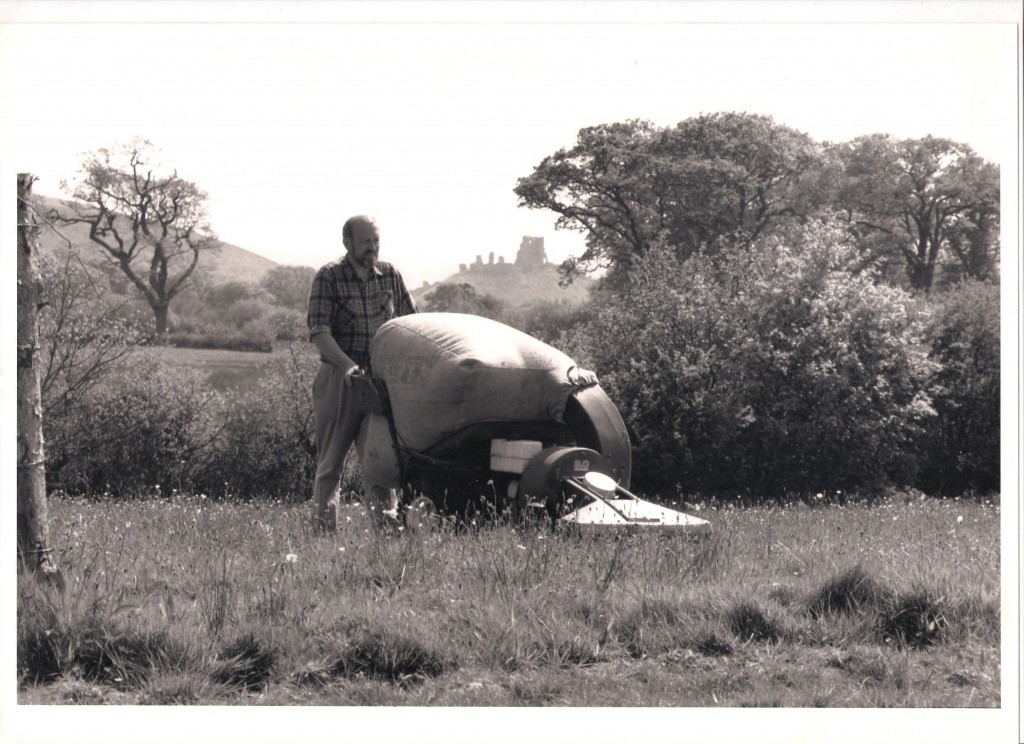

Collecting the Seed

We have developed two light and low impact machines, both with hydraulically adjustable headers, these allow us to follow contours and changes in swarth height whilst avoiding ant communities and scrub that are common in most sites. Each machine has a curtain to exclude invertibrates

Cooling and Drying

The seed is cooled using forced air and taken to our farm, here it is fully cooled and dried carefully, this first 48 hour period being crucial to the viability of the seed.

Threshing

Once dry, the material is threshed using a closed loop system, this allows us to make sure we keep all of the seed collected

Cleaning and Storage

The seed is then cleaned through several stages and refrigerated to retain viability. Seed for civil engineering projects such as pipeline restoration benefit from these controlled conditions and this greatly improves the storage live and viability of harvested seed

Analysis

The representation of species from each lot of clean seed is recorded. This helps monitoring of the development of each site and economic sowing of the seed.